Jan. 11, 2022, by Cheolhee Lee and Junsik Oh

From Sketch to 3D Print, Industrial Design Students Create Moushi

Fun and intuitive design textured with Substance 3D Painter

We think that the most attractive side of product design is that it provides an experience to users through physical interaction.

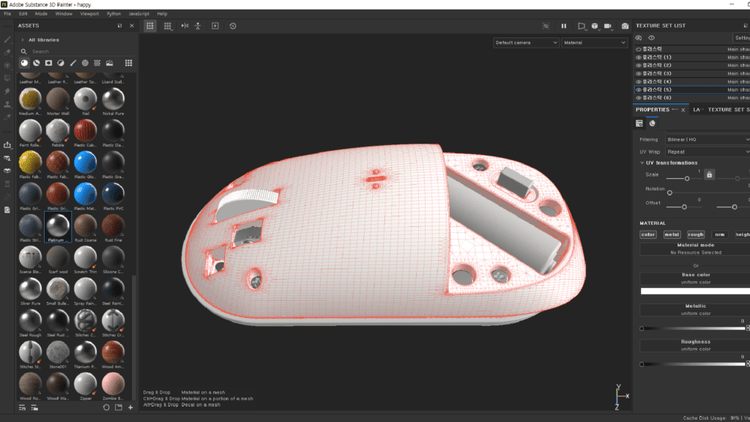

Our team is very interested in Behance. I log in every day to see the work of other designers and featured works selected by curators, and before the rendering process of the Moushi project, I saw the curator field called Substance 3D Painter for the first time. As I said previously, we are very interested in various methods of visualization. So, while I was learning information about the program through YouTube videos, I decided to use Painter for the Moushi project.

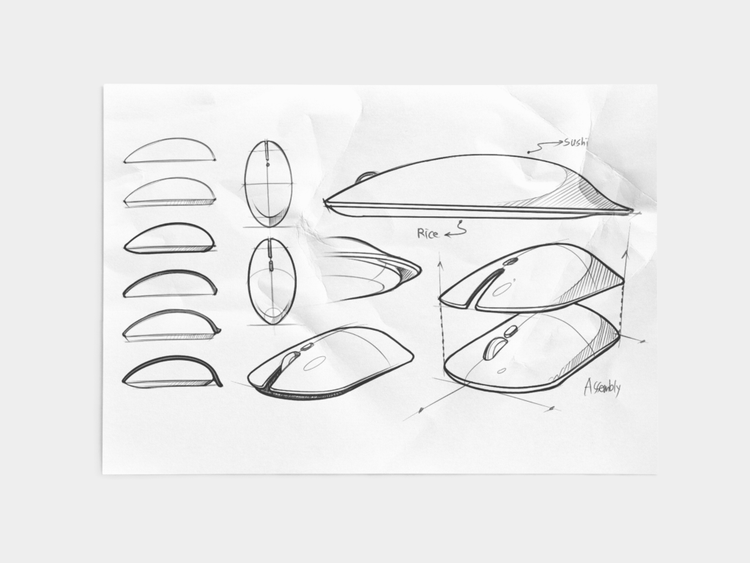

This design is an idea inspired by the similarity between the assembly method of the mouse and the composition method of sushi, and allows the user to customize the design of the mouse to the desired configuration. Furthermore, we want to provide a new experience by penetrating the user’s work environment needs by making their work environment more delicious and enjoyable.

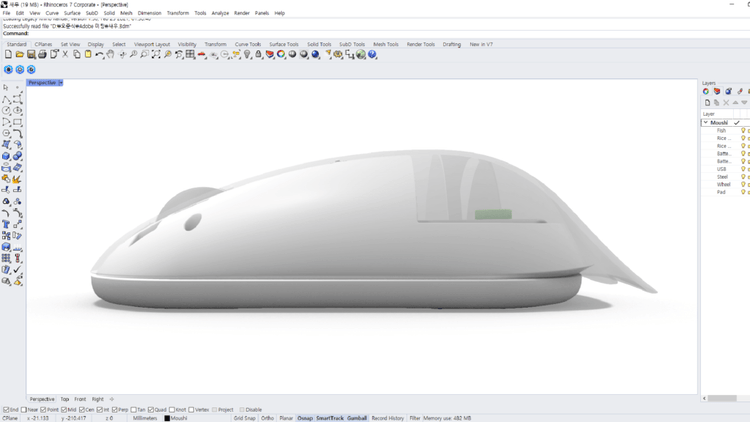

In the process of visualizing the product design, modeling was performed using Rhino, and initial rendering was performed through Keyshot. After that, we introduced Painter and succeeded in reaching an image that was as close as possible to what we had expressed in KeyShot. In particular, various texturing tasks were made easier in Painter.

In addition, the overall development of the project and post-editing was done through Illustrator, Photoshop, and Stock.

For the first time, modeling became a reality using a 3D printer. Since then, we have been able to check whether the print is convenient for users to use, looking at things such as size and thickness. After that, we found a convenient form by checking the identified problems, re-modeling, and repeating the process of outputting to the 3D printer. After that, the modeling was modified by checking the part to be combined with the bottom module of the mouse. Finally, we were able to find the perfect form of Moushi.

As we said earlier, mass-producing products as a student is not an easy task. However, additional support will be available from KDM+ from 2022. Until then, we are currently in the process of intellectual property registration and business registration. After that, we will mass-produce the product through PCB design and internal module design process. We are also willing to sell Moushi once it comes out as a real product.

As a team, we are working on a new project for two months this November-December. This project will use Substance Stager to propose various renderings and environment scenes. It will be published on the web through our Behance accounts (Cheolhee Lee, Junsik Oh). If you’re interested, don’t hesitate to check it out. Thank you!