What is Sublimation Equipment Printing?

Give your designs the clarity and vibrancy they deserve with sublimation printing. Don’t lose your design on the journey from the screen to the printer.

Discover everything you need to know about creating stunning, long-lasting designs using sublimation ink equipment printing with Adobe.

What does ‘sublimation’ mean in printing?

Sublimation printing sounds complex, but you don’t need to be a boffin to understand it. Scientifically, sublimation is defined as changing the solid-state of matter to a vapour state, without becoming liquid. But really, it’s more straightforward than that.

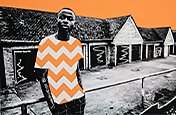

Simply put, dye sublimation equipment uses heat transfer to print an image onto a material. For example, you could use it to print patterns onto fabrics, ceramics or even glass. From crafters and artists to clothing designers, sublimation equipment has a lot of uses. Sublimation and screen printing is a common way to create high-quality tote bags, coasters, mousepads, home decor items and more. It’s also a common printing method in the DIY tshirts and garment printing industry.

The sublimation printing process

By heating ink until it penetrates the surface of your material, sublimation equipment transfers digital images into vibrant, permanent, full-colour prints. Step-by-step, this is how it works:

- Sublimation printing starts with the ink being applied onto a special transfer paper.

- The transfer paper containing the dye is then placed in direct contact with the printing surface.

- This transfer paper is then heated with a heat press. Once correctly heated, the ink turns into a gas, which then embeds into the surface of your material.

- Once the sublimation ink has penetrated the printing surface, the heat is removed. As the ink cools, it solidifies and dries into a permanent image - like a tattoo.

The benefits of sublimation equipment printing techniques

Benefits they provide. If you’re thinking of using sublimation equipment printing, it’s worth knowing the pros and cons:

Pros:

- Longevity. Because sublimation ink printers use heat to fuse ink onto the printing surface, the resulting images are vibrant and durable. They won’t crack, peel or fade - even after seeing the inside of the washing machine. That means you get a lot of wear out of your garment or signage.

- Vibrancy. Sublimation prints are vibrant, accurate and sharp. Because of the reaction of the ink under heat, it physically changes colour, becoming brighter. Additionally, as the ink fuses with the materials, it’s longer lasting. Sublimation ink not just vibrant at first print - it’s vibrant for longer.

- Speed. Dye sublimation equipment is quick - faster than a kettle can boil. It takes just 20-35 seconds to complete the print on a t-shirt or ceramics and about 180-240 seconds on glass.

- Eco-friendliness. The sublimation printing process results in minimum waste as it uses dry ink. Dry inks are infused into the material, which means less wastage compared to a liquid ink. Also, the same print can be used multiple times before fading and it only applies ink to the necessary surface areas.

Cons:

- Colour limitations. Sublimation printing is best suited to white or light, materials as it doesn’t use white ink. Additionally, sublimation inks can’t lighten the base colour. If you’re printing on black, your design may struggle to show.

- Material limitations. To successfully print using sublimation printing techniques, you’ll need to use polyester or high-percentage polyester blends. For glass, ceramic and other hard materials, you’ll need a special poly-coating. If you use sublimation equipment on natural materials, they may simply wash off.

- Creasing issues. If you print on a garment, you could see white streaks due to improper printing. This usually happens around creases or seams and is very noticeable. This means it’s not always a great choice for beginners.

Sublimation equipment you’ll need

Sublimation printing is a great way to customise and create, but you’ll need a few things to start making your own prints.

Sublimation equipment and software

Just like with direct to fabric (DTF) or Cricut jobs, you’ll need a specialist sublimation printer. There are a lot of brands to consider like Sawgrass and Epson, so you’ll want to do a bit of research. Sublimation equipment comes in different sizes, so consider what you’re the substrate you’re printing onto. If you’re printing tablecloths, for example you may not want a paper-sized printer.

Sublimation inks

Sublimation printing requires ink - just like your standard inkjet printer - and these inks will directly correlate to the quality your sublimation equipment prints. So, if you want vivid prints, it’s important to pick the right inks. Try to get a full set of inks so you’ve got a full palette of colours.

Sublimation paper

Sublimation paper is needed to transfer the heated ink designs to your chosen media. You can get these in a range of sheet sizes, making it simple to choose the ideal size for your designs.

Heat press

You may be tempted to use an iron to print - and you can, but it can be impractical to use. If you’re looking to add a professional finish to your prints, you’ll want to invest in a heat press. These devices can be large, produce a consistent heat and are perfect for fabrics and paper. If you’re looking to print on ceramics, you may want to consider a mug oven to batch print.

Sublimation blanks

Sublimation blanks are the products you want to print on - like a canvas. Your average, run-of-the-mill sublimation equipment handles paper, but advanced printers can tackle mugs, pillows, trays and more.

Remember, your blanks need to be - as the name suggests - blank and either made of polyester or covered in a polyester coating to print properly. You can print without polyester, but it probably won’t stick.

Sublimation equipment FAQs

What’s the difference between dye sublimation equipment and regular printing equipment?

Compared to your regular home printer, sublimation equipment produces more vibrant, resilient designs that are resistant to fading. However, sublimation equipment can be more expensive.

What is sublimation printing equipment good for?

Sublimation printing equipment is great for printing patterns on polyester materials, as it can create vibrant, longer-lasting, non-peeling designs.

Can you do sublimation printing at home?

Yes, sublimation equipment can be used at home. You’ll need a sublimation printer and ideally a heat press - though some people use their domestic irons. It’s not as straightforward as a standard ink-jet home printer, but you could create stunning designs from home with sublimation equipment.

Create sublime designs for printing with Photoshop

Make incredible designs with a full suite of tools and features in Adobe Photoshop. You can then bring your designs to life by printing them on a variety of canvases.

You might also be interested in…

Set a mood with secondary colours.

In this secondary colours beginner's guide, discover how different colour combinations can help you to make a splash with attention-grabbing work.

Add complex watercolour textures to your digital paintings.

Learn how background textures can bring depth to digital watercolour paintings.

Create professional-quality backgrounds for any kind of media.

Discover how to craft professional-quality backgrounds for presentations, desktops and other projects.